STRAPPING MACHINES: Semi-automatic strapping - Semi-automatic strapping machines are used to apply plastic straps to packages or bundles in a variety of industries, including manufacturing, warehousing, distribution, and shipping. These machines ty ...

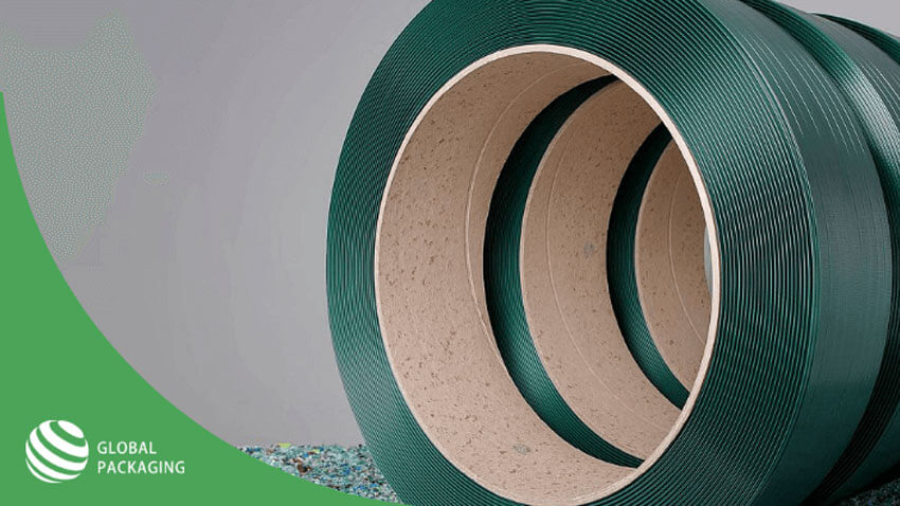

Recyclable PET Strap for Sustainable Strapping Solutions

With sustainability being the new focus for the packaging industry, there have been many innovations when it comes to the production use of existing equipment, with one of the latest additions being the recyclable PET strap. Made of polyethylene tereph ...

PET Straps or Steel Straps

When it comes to strapping, straps are made of various materials and they consist of different configurations. The most commonly used straps are steel and plastic straps, which are also known as PET straps. While steel straps provide an advantage when it ...