STRAPPING MACHINES: Semi-automatic strapping - Semi-automatic strapping machines are used to apply plastic straps to packages or bundles in a variety of industries, including manufacturing, warehousing, distribution, and shipping. These machines ty ...

Types of protective packaging for shipping

Often confused with parcels and packages that are shipped on a day-to-day basis, protective packaging is mainly used to shield mailed items from any wear and tear. It is no surprise that transportation makes packages and parcels prone to physical damage, ...

What are the 5 reasons for packaging?

Packaging is the art and science of extending a protective layering to a product orcommodity, for convenient transport, storage, logistics, and sale. It is widely regarded as animportant marketing subset, which aids the seller in minimizing external dama ...

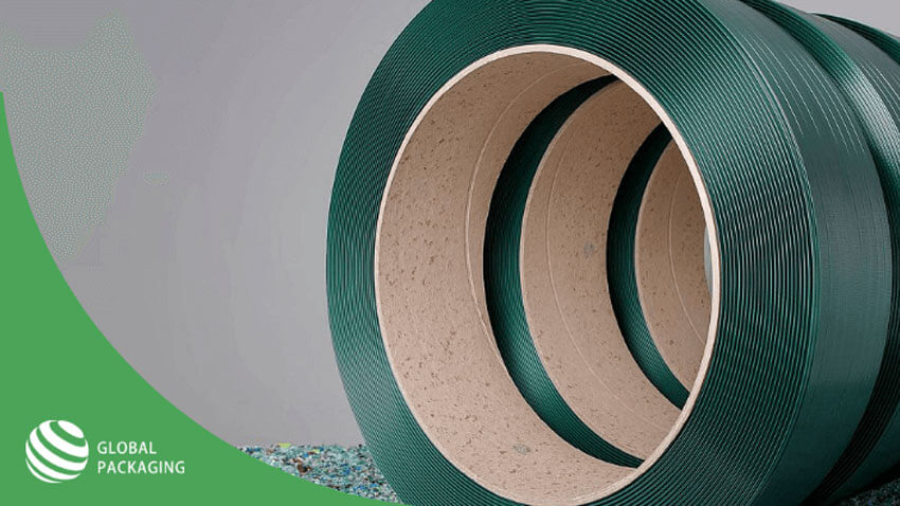

Recyclable PET Strap for Sustainable Strapping Solutions

With sustainability being the new focus for the packaging industry, there have been many innovations when it comes to the production use of existing equipment, with one of the latest additions being the recyclable PET strap. Made of polyethylene tereph ...

Importance of Robotic Pick and Place Machines

Pick and place robots are commonplace in many industries. These robotic systems may be employed for various reasons. A robotic pick and place machine can be assembled in a packaging line to place products or packages from one conveyor to another, where a ...

Importance of Packaging Solutions in Food Industry

Packaging is an essential operation in the food industry which uses a variety of solutions to carry out cartooning, shrink wrapping, pelleting, capping, labelling, etc. The good news about these packaging solutions is that a number of automated machines ...

Rising Demand of Robotic Case Erectors in Indian Market

Introduction of robotics has revolutionized all sectors but the effect is more pronounced in industries where heavy-duty tasks comprise operations in bulk. Incorporation of robotics into automatic case erectors is a recent addition, and this change has p ...