In today’s fast-paced industrial world, efficiency and reliability are key When it comes to packaging, the importance of secure, efficient, and reliable solutions cannot be overlooked. Strapping machines are an essential part of the packaging process, ensuring that products are tightly sealed and protected during transit. Whether it’s for industrial goods, e-commerce packages, or retail products, a good strapping machine helps businesses maintain a smooth workflow while safeguarding their shipments. Delhi, a thriving industrial hub, has emerged as a key location for top-quality strapping machine manufacturers. Known for their innovation, durability, and cost-effectiveness, manufacturers in Delhi are setting new benchmarks in the packaging machinery sector. In this blog, we’ll explore the key factors to consider when choosing a Strapping Machine Manufacturer in Delhi and why the city has become a go-to destination for businesses seeking cutting-edge packaging solutions.

Brief Overview Of Strapping Machines

Strapping machines are electro mechanical devices used to secure items or packages by applying a strap (usually made of plastic, steel, or polyester) around them. These machines help to tightly seal products, making them more secure and stable during handling, storage, and transport. By applying a strap, the machine ensures that goods are protected from shifting, damage, or contamination during movement, whether it’s across a warehouse, on a pallet, or during transit.

Strapping machines are essential tools in various industries that require the packaging of products in a safe, secure, and efficient manner. These machines can significantly reduce the time and effort required for manual strapping, improve packaging consistency, and ensure better protection of goods.

Types of Strapping Machines

1. Semi-Automatic Strapping Machine: A semi-automatic strapping machine is a type of equipment designed to apply straps to packages, cartons, or other products manually with some automated functions. The operator loads the product into the machine, adjusts the strap around the package, and then initiates the strapping cycle. The machine automatically feeds, tightens, and seals the strap. Once the cycle is complete, the operator removes the strapped package. These machines are ideal for businesses with moderate production needs, offering a balance of automation and operator control.

Key Features:

- Requires manual placement of the product

- Operator involvement for loading and unloading

- Cost-effective for mid-range packaging needs

- Commonly used for general packaging in smaller industries

2. Automatic Strapping Machine for Pallets: Automatic strapping machines for pallets are designed specifically for securing large loads on pallets. These machines can automatically strap multiple pallets without requiring much operator intervention. Once the pallet is loaded onto the machine, it automatically feeds the strap, tightens it, seals the strap, and cuts it. These systems are ideal for high-volume production environments, such as warehouses or distribution centers, where large quantities of palletized goods need to be securely strapped for storage or shipment.

Key Features:

- Fully automatic, reducing human labor

- Often used for large, bulk palletized goods

- Helps speed up operations and ensures consistent strapping quality

- Ideal for high-volume operations

3. Online Strapping Machine: Online strapping machines are integrated directly into the production or packaging line. These machines are designed to work automatically as products move along the production or conveyor line, without requiring manual input after setup. As products pass through the machine, it automatically applies the strapping. This type of machine is used for continuous production or assembly lines where large quantities of products need to be strapped efficiently and consistently.

Key Features:

- Integrated with production or conveyor lines

- Automatic operation with minimal human intervention

- Ideal for high-speed packaging environments

- Efficient for mass production and high throughput

4. Pallet Strapping Machine: Pallet strapping machines are specialized equipment designed to strap pallets, which are typically used to transport large or heavy products. These machines can be either semi-automatic or fully automatic, and they are tailored to handle larger and bulkier items. Pallet strapping machines are critical in industries like logistics, warehousing, and shipping, where goods need to be securely bundled together to prevent shifting or damage during transportation.

Key Features:

- Tailored specifically for strapping palletized loads

- Can be semi-automatic or fully automatic

- Ensures secure packaging for transportation or storage

- Reduces damage and improves load stability during transit

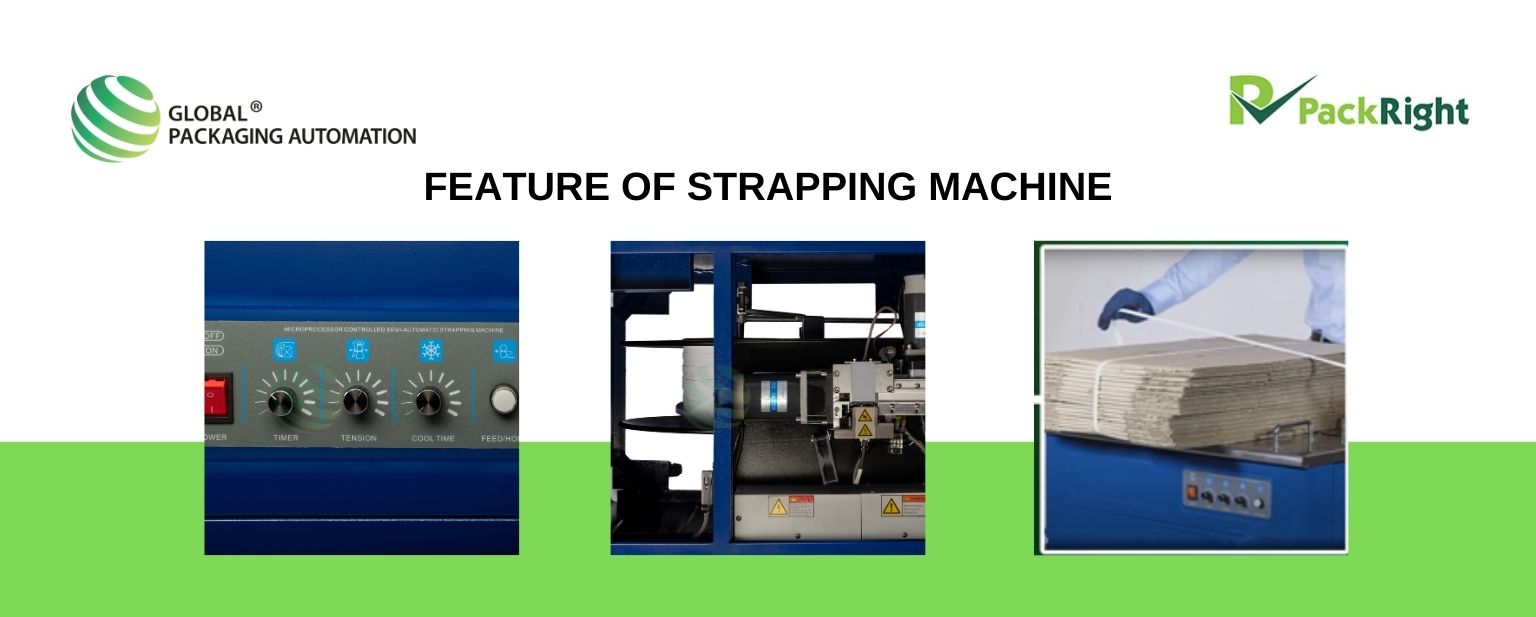

Key Features to Consider in a Strapping Machine

When selecting a strapping machine for your packaging operations, it is important to evaluate its key features to ensure efficiency, reliability, and cost-effectiveness. Here are the essential features to consider before making a purchase:

- Durability and Build Quality: A high-quality strapping machine should be built with durable materials such as stainless steel or reinforced metal components to withstand continuous operation. A robust machine ensures longevity and minimizes the need for frequent repairs or replacements, making it a cost-effective investment for businesses.

- Speed and Efficiency: The speed of a strapping machine directly impacts the productivity of packaging operations. Machines with higher strapping speeds can handle large volumes of packages in less time, improving overall efficiency. When selecting a machine, businesses should consider their packaging volume requirements and choose a model that aligns with their operational needs.

- Compatibility with Different Strap Materials: Different packaging applications require different types of strapping materials, such as polypropylene (PP), polyester (PET), or steel straps. A good strapping machine should be compatible with multiple strap materials to provide flexibility for various packaging needs. Compatibility ensures that businesses can switch between strap types based on load requirements without needing multiple machines.

- Ease of Operation and Maintenance: User-friendly controls and an intuitive design make it easier for operators to use the machine efficiently. Features such as automatic strap feeding, adjustable tension settings, and digital displays enhance usability. Additionally, a machine that is easy to maintain with accessible parts and minimal downtime ensures smooth long-term operation.

- Safety Features: Safety is a critical factor when using industrial packaging machines. A reliable strapping machine should have essential safety features such as emergency stop buttons, automatic shut-off functions, and protective covers to prevent accidents. Compliance with industry safety standards ensures that operators can use the machine without risk of injury.

Benefits of Choosing a Reliable Strapping Machine Manufacturer

When selecting a Strapping Machine Manufacturer in Delhi, it is crucial to choose a reliable and reputable company. A trusted manufacturer ensures that businesses receive high-quality machines that enhance packaging efficiency and provide long-term benefits.

- High-Quality and Durable Machines: A dependable manufacturer provides strapping machines that are built with precision and high-quality materials. These machines are designed to withstand continuous usage and harsh working conditions, ensuring long-term durability and reliability. Investing in a well-built strapping machine reduces maintenance costs, minimizes downtime, and enhances packaging efficiency.

- Customization Options for Specific Industry Needs: Every industry has unique packaging requirements. A reliable strapping machine manufacturer offers customization options to meet specific business needs. Whether it is adjusting machine settings, modifying strap tension, or integrating automated features, customization ensures that the machine functions optimally for various packaging applications.

- Advanced Technology and Innovation: Leading manufacturers continuously invest in research and development to introduce advanced features in their strapping machines. This includes automation, digital controls, and smart sensors that improve packaging accuracy and efficiency. By choosing a manufacturer that focuses on innovation, businesses benefit from modern solutions that enhance productivity.

- After-Sales Service and Technical Support: A reliable manufacturer provides excellent after-sales support, including machine installation, training, troubleshooting, and regular maintenance. Technical assistance ensures that any operational issues are resolved quickly, minimizing production delays. Having access to a dedicated support team enhances the overall user experience and ensures smooth machine performance.

- Cost-Effective Solutions for Businesses: Investing in a high-quality strapping machine from a reputable manufacturer helps businesses save costs in the long run. Reliable machines require fewer repairs and replacements, reducing maintenance expenses. Additionally, efficient strapping machines optimize packaging processes, leading to higher productivity and lower labor costs.

- Compliance with Industry Standards and Safety Regulations: Reputable manufacturers adhere to industry standards and safety regulations when designing and manufacturing strapping machines. This ensures that the machines operate safely and efficiently, reducing workplace hazards and improving overall packaging quality.

Conclusion

In conclusion, choosing the right strapping machine is crucial for ensuring efficiency, durability, and cost-effectiveness in packaging operations. As a leading strapping machine manufacturer in Delhi, we take pride in offering high-quality, reliable, and technologically advanced strapping solutions to meet the diverse needs of our customers. Whether you’re in the logistics, manufacturing, or retail industry, investing in the right strapping machine will not only streamline your operations but also enhance the security of your packages.

If you’re seeking a reliable packaging partner to safeguard your goods during storage and transit, Global Packaging Automation is here to help. For inquiries or to purchase a Strapping Machine Manufacturer in Delhi, reach out to us at +917738819711 or email us at info@globalpackindia.com. Watch our latest video on our channel, Global Packaging Automation LLP. Looking for top-quality strapping equipment at competitive prices? Global Packaging Automation offers a diverse selection of dependable packaging solutions designed to meet your specific business needs. Click here to browse our products and find the ideal solution for your packaging requirements!